Based on the P&ID’s of the Process Plant and the requirements of the customer SanCo Automation develops a PLC Automation Design.

This design exists of:

sequence engineering and

object design.

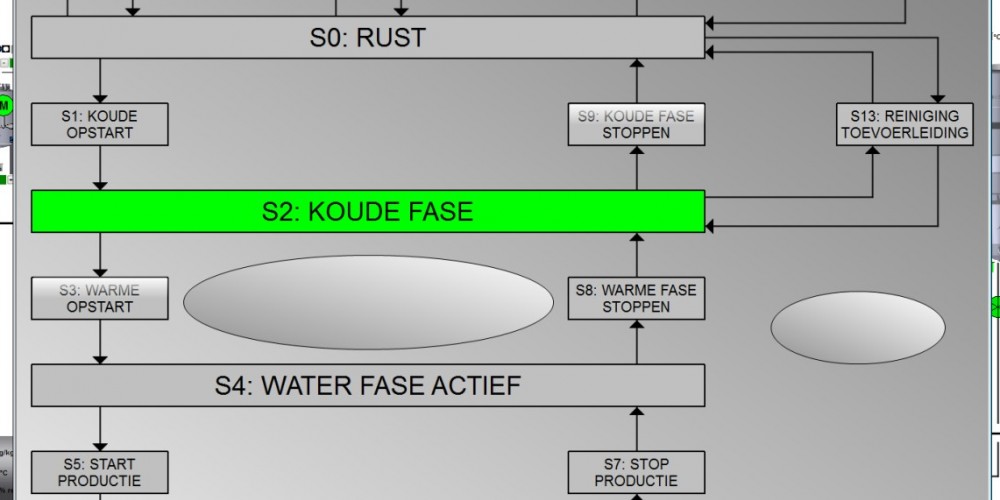

The sequence engineering is a structured document which exists of a main program sequence (organizer) and all necessary subsequence’s (start up, water operation, etc.). The object design is a design of all the automated objects (valves, instruments, motors, standalone machines, PID control, etc..). Each object has its own generic control program (function blocks). At SanCo Automation we have a big library of function blocks with all functionalities we think are required for optimal (efficient and operator friendly) plant control.

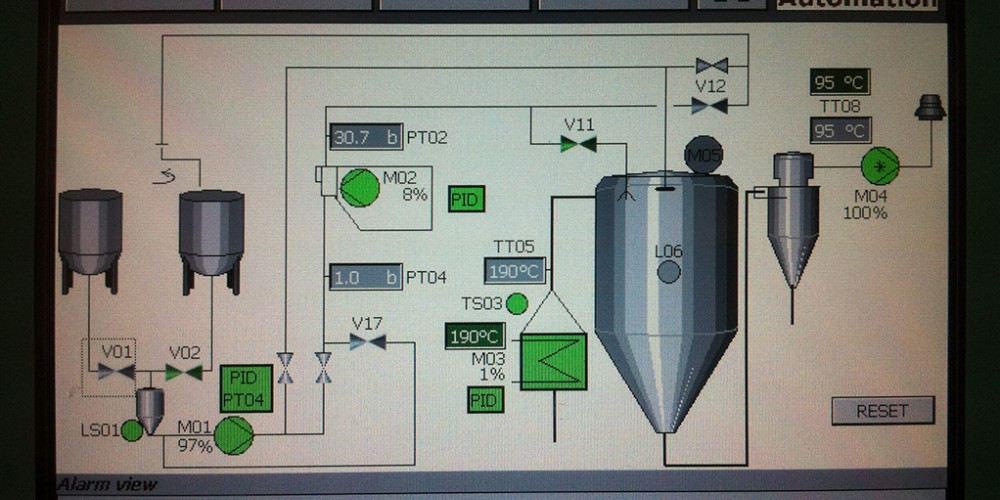

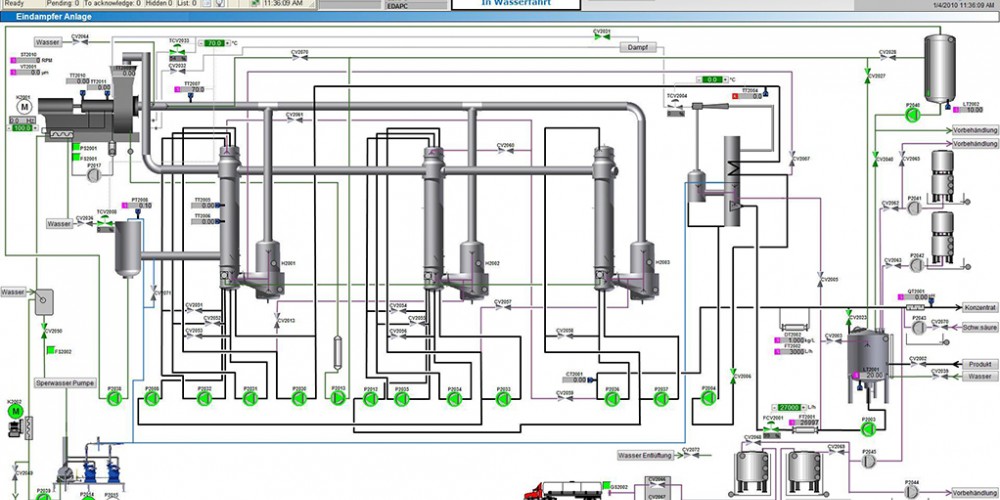

Sanco Processing can deliver an operator control interface with all the needs you can think of: Look and Feel. SanCo Automation puts itself in the seat of the Operator at time of picture engineering. Instead of symbolic pictures, 3D rendered images of the installation parts is a standard which gives Operators/Technicians recognition of the installation itself.

User-friendly alarm view, Alarms are displayed on the screen. The display of the message information can be exactly adapted to the needs of the operator.

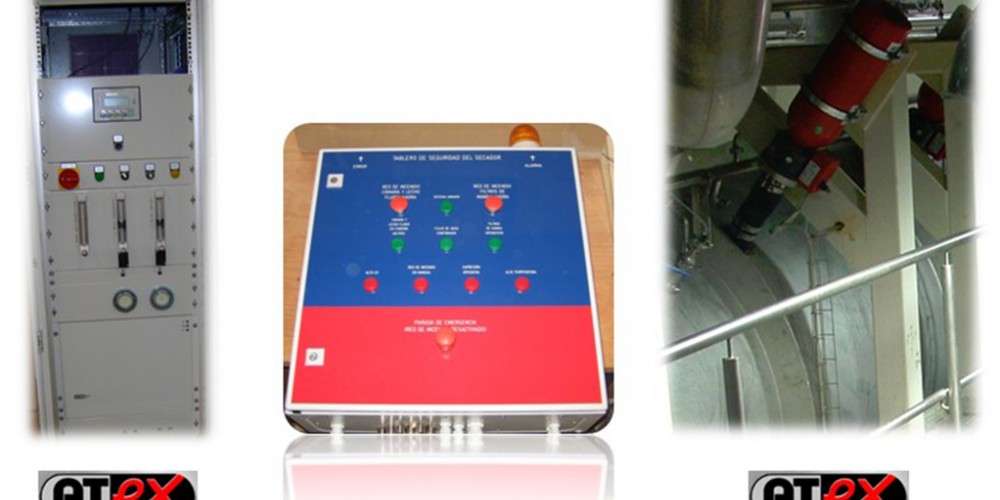

We deliver a flexible, reliable, user friendly and efficient control system to ensure a good process.