Sanco Processing manufactures and install processes to concentrate liquids also to make them ready for, for example, spray drying. For that we use evaporators, TVR and MVR or a combination of both.

Our evaporators are used mainly in dairy (food) related processes, but are also suitable for waste water and (light) chemical processes. The reason of evaporation is the removal of water. From a liquid stage into a gas stage (vapor). These kind of processes ask a lot of energy, steam for TVR and electricity for MVR.

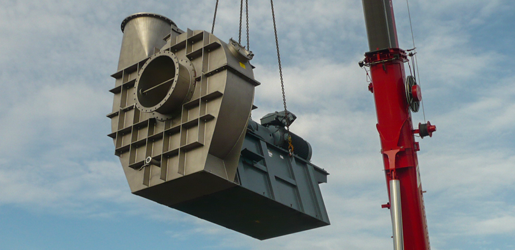

MVR

MVR ( mechanical vapor recompression) evaporators are using a ventilator to compress the vapor stream. This compression gives the necessary temperature difference between the condensing vapor and the warm evaporating liquid. Most MVR evaporators exists out of one effect with multiple passes. An MVR evaporator does not need steam, except for start up. MVR evaporators are more efficient then TVR evaporators but are more expensive in initial purchase. The ventilator uses a lot of electrical energy. The choice between TVR or MVR is often the choice between steam or electricity. A combination form both is also often used to reach higher concentrations in the final product.

TVR

TVR (thermal vapor recompression) evaporators are using steam for evaporation, mostly with thermo compression to re use the vapor temperature and reheat. TVR evaporators exists out of several effects, normally three up to seven effects. The more effects the more efficient the TVR will be on steam usage per kilogram evaporated product. Preheaters can be build in easily in effects or separators to use the heat optimal.